LNF992

LNF992

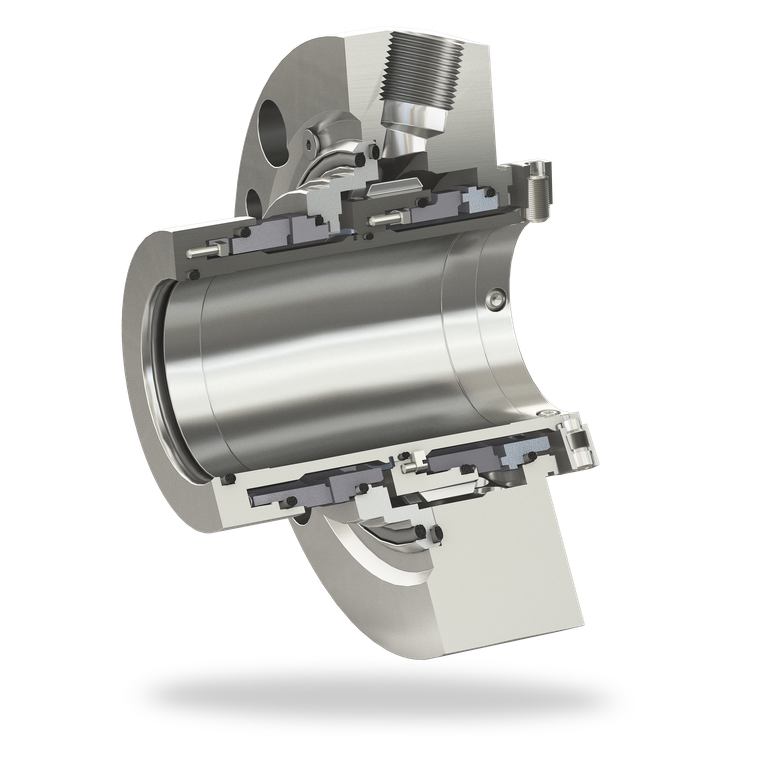

| Item | Description |

| 1,8 | Seal ring |

| 2, 7, 9, 14, 16, 17, 24, 25 | O-Ring |

| 3, 10 | Thrust ring |

| 4, 11 | Spring |

| 5, 12 | Mating ring |

| 6, 13, 21, 27, 30 | Pin |

| 15 | Seal sleeve |

| 18 | Labyrinth |

| 19 | Adapter sleeve |

| 20, 26 | Gland plate |

| 22 | Adapter |

| 23 | Retaining ring |

| 28, 33 | HSH cap screw |

| 29 | Drive collar |

| 31 | Set screw |

| 32 | Setting device |

GBO Gas barrier OUT

GBI Gas barrier IN

LNF992

Features

- API 682 Category 2 and 3, Type A, Arrangement 3 seal

- Dual seal in face-to-back arrangement

- Gas-lubricated

- Balanced

- Cartridge unit

- Stationary multiple springs

- Independent of direction of rotation

- Solid seal faces

Advantages

- Non-contacting stationary spring unit design

- No process fluid penetration into the seal faces, no leakage to the atmospheric side

- Appropriate to slurry fluid

- Applicable inboard seal design for reverse and positive pressure

- Low power consumption

Materials

Seal rings: Silicon carbide SSiC (Q1),

High density carbon graphite

Mating rings: Silicon carbide SSiC (Q1)

Secondary seals: FKM (V)

Springs: Hastelloy® C-276 (M5)

Metal parts: CrNiMo steel 316 (G)

High density carbon graphite

Mating rings: Silicon carbide SSiC (Q1)

Secondary seals: FKM (V)

Springs: Hastelloy® C-276 (M5)

Metal parts: CrNiMo steel 316 (G)

Standards and approvals

- API 682 / ISO 21049

- API 682 4th ed. Cat. 2/3 - 3NC-FB

Recommended applications

- Chemical industry

- Petrochemical industry

- Oil and gas industry

- Refining technology

- CCUS

- Alternative fuels production

- Gases and liquids

- Hazardous media

- Environmetal harmful media

- Monomeres

- API 610 / ISO 13709 pumps

- Process pumps

Recommended piping plans

Process side:

API Plan 01

API Plan 02

API Plan 03

API Plan 11

API Plan 12

API Plan 21

API Plan 22

API Plan 31

API Plan 32

API Plan 41

Between seals:

API Plan 74

API Plan 01

API Plan 02

API Plan 03

API Plan 11

API Plan 12

API Plan 21

API Plan 22

API Plan 31

API Plan 32

API Plan 41

Between seals:

API Plan 74

Similar products

APItex-S

- API 682 Category 1, Type A, Arrangement 1 seal

- Single seal

- Balanced

- Cartridge unit

- Independent of direction of rotation

- Solid seal face

- Solid seat

APItex-T

- API 682 Category 1, Type A, Arrangement 2 or 3 seal

- Dual seal in face-to-back arrangement

- Balanced

- Cartridge unit

- Independent of direction of rotation

- Solid seal faces

- Solid mating rings

CGSH-KD

- API 682 Category 2 and 3, Type A, Arrangement 3 seal

- Dual seal in back-to-back arrangement

- Cartridge unit

- Independent of direction of rotation

(with U-grooves) - Gas-lubricated

- Contact free operation, no friction

- Rotating multiple springs